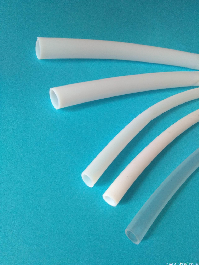

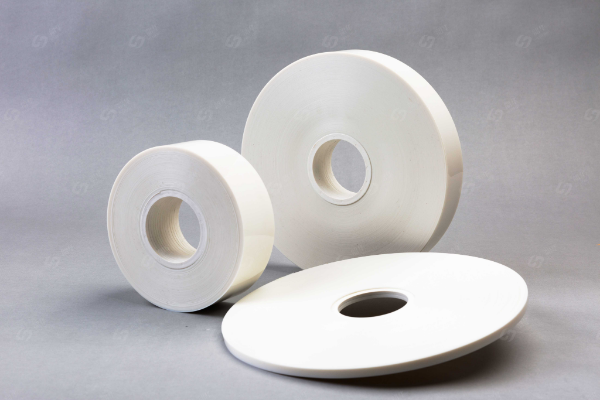

Teflon

Teflon is an inert polymer with excellent corrosion resistance, high temperature resistance, flame retardancy and wear resistance, as well as good dielectric properties and temperature stability. It can be used in a wide temperature range from -200 ℃ to + 260 ℃, so it is widely used in industries requiring high temperature resistance and high viscosity.

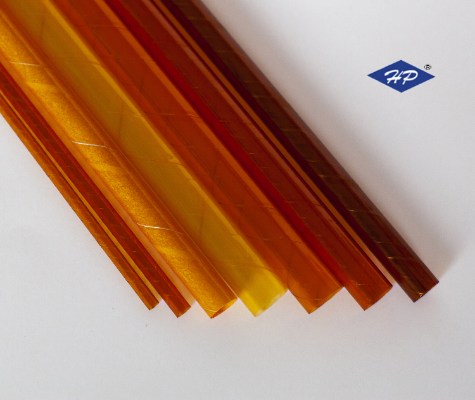

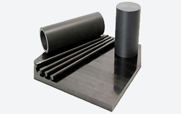

PI-polyimide Plastic

PI material has excellent high temperature stability, excellent mechanical properties and excellent chemical corrosion resistance, which makes it widely used in many fields. PI material has extremely high glass transition temperature and thermal expansion coefficient, which can maintain stable size and performance in high temperature environment. At the same time, it has excellent wear resistance and fatigue resistance, which is suitable for componants manufacturing under long-term high-load working conditions.

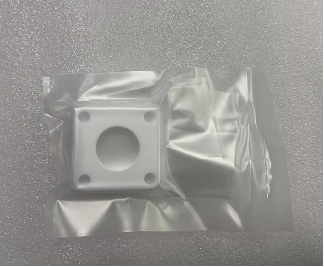

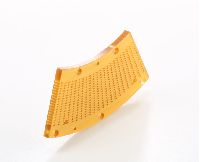

PEEK-polyetheretherketone

PEEK is widely used in aerospace, automotive, medical equipment and electronics due to its high temperature stability, chemical resistance and mechanical properties. Its high strength, wear resistance and high temperature resistance make it ideal for the manufacture of a wide range of demanding components, providing a reliable and high-performance solution for these areas.

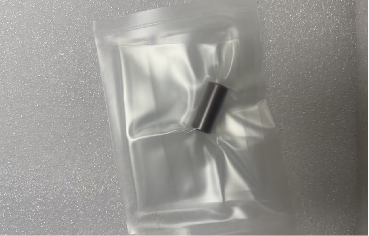

PPS-Polyphenylene Sulfide

With excellent high-temperature stability, excellent chemical corrosion resistance and excellent mechanical properties, PPS is suitable for applications in a variety of harsh environments, such as electronic communications, petrochemical environmental protection, aerospace and other fields, providing reliable solutions for a variety of high-end applications.

PBI-Polybenzimidazole

PBI has excellent high temperature stability, mechanical properties (including high strength, high stiffness and wear resistance), chemical stability and corrosion resistance, electrical insulation, thermal aging resistance and low smoke, low toxicity and other characteristics. These characteristics make PBI widely used in aerospace, automotive, electronics, chemical industry and other fields, providing reliable solutions to solve the problems of high temperature, high strength, wear resistance, corrosion resistance and so on.

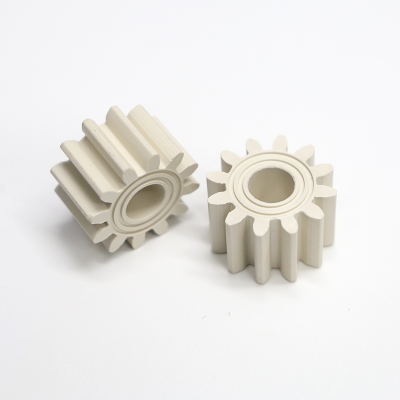

POM-Polyoxymethylene

POM is an excellent engineering plastic with excellent properties such as high hardness, high rigidity, wear resistance, impact resistance, heat resistance and chemical corrosion resistance. Widely used in automotive parts, electronic devices, mechanical parts and other fields.

PET-polyester Resin

PET is a common polyester plastic with excellent physical and chemical properties, as well as excellent transparency, high strength, heat resistance, chemical corrosion resistance, tensile resistance and good processability. It can be used to prepare products of various shapes through injection molding, extrusion molding and other processes. PET is widely used in food packaging, textiles, electronic products, medical devices and other fields because of its excellent performance.

Chemical Cleaning Agents

Industrial chemical cleaning agents possess potent decontamination capabilities, encompassing acidic, alkaline, descaling, degreasing, paint removal, and other varieties. These agents effectively eliminate oxides, grease, scale, and other contaminants from metal and ceramic surfaces, ensuring equipment cleanliness and extending service life. They enhance equipment cleaning efficiency, curtail maintenance expenses, and contribute to elevated production quality and safety standards. Indispensable in industrial cleaning and maintenance, these agents play a pivotal role in optimizing operations.