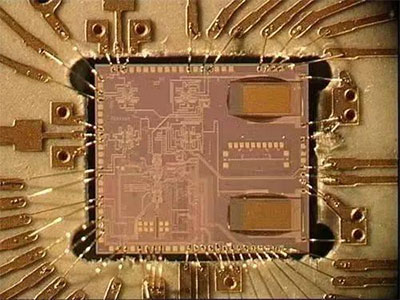

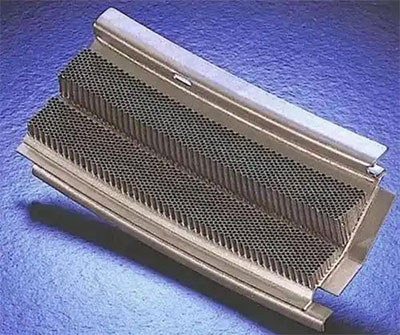

Precision Alloys

Precision alloys are a class of metallic functional materials engineered for specialized physical properties. Precise control over alloy composition and microstructure allows for the attainment of superior electrical, thermal, and mechanical performance. These alloys are typically manufactured using high-purity metal feedstocks, processed through precision melting, forming, and heat treatment techniques. Key properties include: unique, stable electrical resistance; desirable elastic properties and mechanical strength; controllable thermal expansion coefficients; and robust environmental resistance. These characteristics enable stable performance under extreme temperatures, corrosive environments, or in high-frequency applications. Precision alloys are fabricated into various forms, including fine wires, strips, and rods, based on specific application requirements. As critical fundamental materials for modern industry, precision alloys find wide application in high-end areas such as sensors, measuring instruments, and electronic components, providing reliable signal transmission, electro-mechanical conversion, and temperature control functions across a range of precision devices, including potentiometers, relays, strain gauges, accelerometers, and hydrogen storage systems.

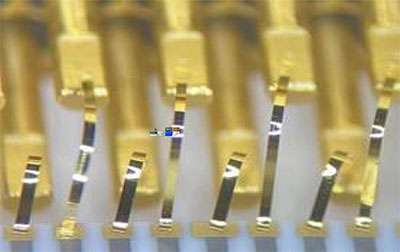

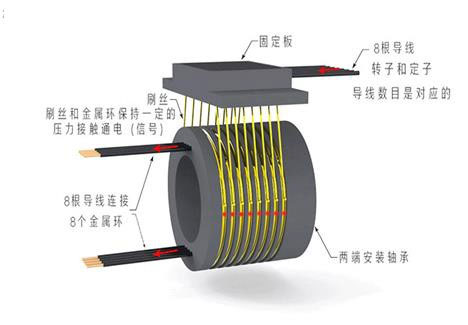

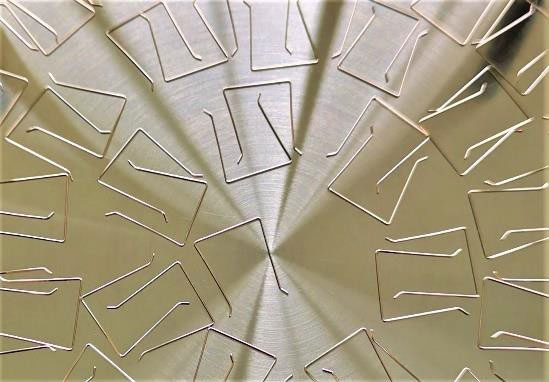

Electrical Contacts

Electrical contact materials are essential functional components that ensure reliable connections and efficient conductivity in electrical devices. Their performance influences switch efficiency, contact stability, and lifespan. Made primarily from gold-based, palladium-based, and silver-based alloys, these materials are processed into various forms such as contacts, rivets, and stampings using precision techniques. Key properties include high electrical and thermal conductivity, arc erosion resistance, stable contact resistance to minimize energy loss, and mechanical durability for long-term use. They are used in appliances, slip rings, motors, smart meters, and a wide range of electronic equipment.

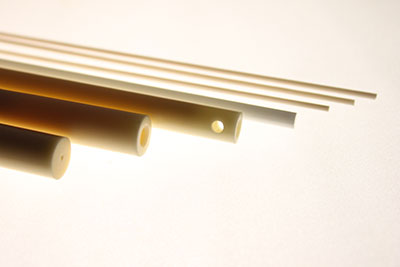

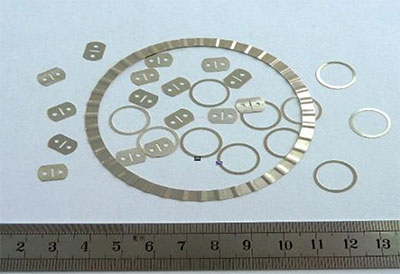

Brazing Materials

Brazing materials are critical functional materials for achieving high-strength joints between dissimilar materials. Through precise alloy design and process control, they ensure reliable connections under various conditions. This system includes precious metal alloys such as gold- and palladium-based, as well as conventional alloys like silver-, copper-, and nickel-based, available in forms such as strips, pastes, and wires. Key features include wide temperature adaptability, compatibility with multiple materials (enabling metal-to-metal, metal-to-ceramic, and metal-to-graphite joints), and low-stress bonding to minimize thermal deformation and maintain structural integrity. These properties make them ideal for engines, precision electronic packaging, motor equipment, and other advanced manufacturing applications, providing dependable solutions for complex joining requirements.

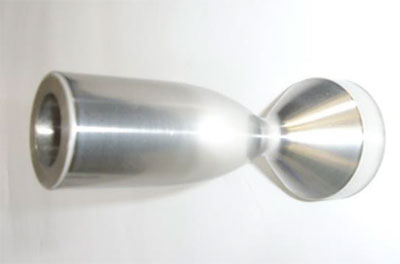

High-Temperature Materials

High-temperature materials are specialized alloys that maintain structural stability and functional properties under extreme thermodynamic conditions, providing essential solutions for high-temperature environments. They primarily include platinum-group high-temperature alloys such as Pt-Rh, Pt-Ir, Ir-Rh; Ir/Re composites; and HfO-based coating systems. These materials exhibit excellent high-temperature stability, oxidation and corrosion resistance, and superior thermo-mechanical properties, meeting the demands of severe high-temperature applications. Widely used in rocket nozzles, engine temperature sensors, and traveling wave tubes, continuous material innovation and process optimization enable these materials to reliably support extreme industrial environments while expanding the performance limits of high-temperature applications and driving technological advancement.